INVESTIGASI KOROSI PIPA FLOWLINE CARBON STEEL PADA SISTEM PRODUKSI MIGAS DAN PENERAPAN SOLUSI PROTEKTIF

DOI:

https://doi.org/10.31949/j-ensitec.v11i02.13508Abstract

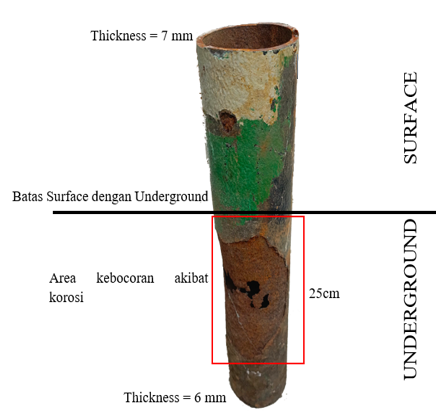

Corrosion in flowline pipes represents one of the critical challenges frequently encountered in the oil and gas industry, particularly within fluid transportation systems in the upstream sector. This issue significantly compromises material performance, incurs substantial economic losses, and poses serious occupational safety risks. Carbon steel, commonly used in flowline pipes, is highly susceptible to corrosion due to exposure to aggressive environments, including high humidity, formation water, and corrosive gases such as H₂S and CO₂. In line with the growing demands for infrastructure reliability and compliance with safety standards, effective corrosion mitigation has become increasingly urgent. The degradation of pipe integrity due to corrosion can jeopardize the long-term reliability of fluid transport systems, potentially leading to severe operational disruptions and escalating maintenance costs. This study aims to investigate the primary causes of corrosion and evaluate the effectiveness of applied mitigation strategies on flowline pipes at a production facility. The methods examined include the application of protective surface coatings and the use of wrapping systems to inhibit direct contact between the metal and corrosive agents. Additionally, pipe wall thickness measurements were conducted to estimate the remaining service life of the flowline system based on the extent of corrosion-induced degradation. The findings of this study are expected to offer technically sound and practically applicable recommendations for corrosion control, thereby enhancing operational reliability and contributing to the sustainable performance of oil and gas infrastructure.

Keywords:

Flowline pipe, Carbon steelDownloads

References

[1] Abdoel Goffar. (2011). Rancangan Dasar Perhitungan Proteksi Katodik Dengan Menggunakan Anoda Korban pada Struktur Baja Anjungan Minyak di Lingkungan Air Laut. Majalah LPL, 45, 82. Jakarta.

[2] Afandi, Y. K., & Arief, I. S. (2015). Analisa laju korosi pada pelat baja karbon dengan variasi ketebalan coating. Jurnal Teknik, 4(2). Institut Teknologi Sepuluh Nopember.

[3] Aji, A. B., Santosa, A. W. B., & Mulyanto, I. P. (2024). Analisa pengaruh variasi ketebalan serta jenis coating pada pelat baja SS400 terhadap laju korosi dan uji adhesi. Jurnal Teknik Perkapalan, 12(2).

[4] Amadi, S. A. (2007). Analysis of corrosion induced failure of oil pipeline in the marine environment and possible control measures. Engineering Failure Analysis, 23, 261–270.

[5] Apriansyah, R. A., & Jatisukamto, G. (2017). Analisis ketahanan korosi pipa A53 pada lingkungan oil sludge dengan metode C-Ring. Jurnal Teknik Mesin, 10(April), 30–35.

[6] Aruan, R. H., Pratikno, H., & Hadiwidodo, Y. S. (2023). Analisa pengaruh suhu material pada pengaplikasian coating epoxy terhadap kekuatan adhesi baja A36. Jurnal Teknik. Institut Teknologi Sepuluh Nopember.

[7] Assholihat, N. K., Karyati, S. M., & Syafrudin, M. (2019). Suhu dan kelembaban tanah pada tiga penggunaan lahan di Kota Samarinda, Provinsi Kalimantan Timur. Ulin Jurnal Hutan Tropis, 3(1), 41–49.

[8] Eka, A. D., Bambang, A., & Bayu, W. K. (2018, Desember). Analisis laju korosi dan lifetime pipa underground baja karbon A53 dengan wrapping protection. Proceedings of National Conference on Piping Engineering and Its Application, 3(1), 193–198.

[9] Eltai, E. O., Musharavati, F., & Mahdi, E. (2019). Severity of corrosion under insulation (CUI) to structures and strategies to detect it. Corrosion Reviews, 0(0). doi:10.1515/corrrev-2018-0102.

[10] Hastuti, K., & Gumelar, R. (2017). Efektivitas proteksi katodik sebagai pengendalian laju korosi pipa minyak pada lingkungan tanah gambut. Seminar Nasional Mitigasi dan Strategi Adaptasi Dampak Perubahan Iklim di Indonesia.

[11] Hussein Farh, H. M., Ben Seghier, M. E. A., Taiwo, R., et al. (2023). Analysis and ranking of corrosion causes for water pipelines: a critical review. npj Clean Water, 6, 65. https://doi.org/10.1038/s41545-023-00275-5

[12] Juanda, M., dkk. (2017). Kajian inhibitor NaNO₂ sebagai pengendalian laju korosi pada stainless steel dalam lingkungan NaCl 3,5%. Surabaya: Program Studi Teknik Kimia, Universitas Pembangunan Nasional “Veteran” Jawa Timur.

[13] Li, P., Zhao, Y., Liu, B., Zeng, G., Zhang, T., Xu, D., Gu, H., Gu, T., & Wang, F. (2017). Experimental testing and numerical simulation to analyze the corrosion failures of single well pipelines in Tahe oilfield. Engineering Failure Analysis, 80, 112–122.

[14] Li, W., Pots, B. F. M., Brown, B., Kee, K. E., & Nesic, S. (2016). A direct measurement of wall shear stress in multiphase flow – Is it an important parameter in CO₂ corrosion of carbon steel pipelines? Corrosion Science, 110, 35–45.

[15] M. H. Sk., Abdullah, A. M., Ko, M., Ingham, B., Laycock, N., Arul, R., & Williams, D. E. (2017). Local supersaturation and the growth of protective scales during CO₂ corrosion of steel: effect of pH and solution flow. Corrosion Science, 126, 26–36.

[16] Okoro, E. E., Kurah, A. M., Sanni, S. E., Dosunmu, A., & Ekeinde, E. B. (2019). Flow line corrosion failure as a function of operating temperature and CO₂ partial pressure using real-time field data. Engineering Failure Analysis, 102, 160–169.

[17] Prabowo, I., Ichsanudin, M., Fuadi, M., Mussoddaq, M., & Paundra, F. (2024). Comparative analysis of water-based inhibitors containing CDEA and TEA against API 5L Grade B. J-ENSISTEC (Journal of Engineering and Sustainable Technology), 11(1), 10180–10188.

[18] Rachmat, A., & nur hidayatulloh, jajang. (2023). Perancangan mesin pemanasan induksi untuk steel forging dengan temperature controller: Indonesia. J-ENSITEC, 10(01), 900–903.

[19] Rahmadi, R., Suprihanto, A., & Haryadi, G. D. (tanpa tahun). Pengaruh dissolved oxygen (DO) terhadap laju korosi stainless steel 304 pada larutan NaCl 0,1 M. Jurnal Teknik Mesin. Universitas Diponegoro

[20] Rustandi, A., Adyutatama, M., Fadly, E., & Subekti, N. (2012). Corrosion rate of carbon steel for flowline and pipeline as transmission pipe in natural gas production with CO₂ content. Makara Journal of Technology, 16(1), Artikel 9.

[21] Saxena, R. C., Biswal, J., Pant, H. J., Samantray, J. S., Sharma, S. C., Gupta, A. K., & Ray, S. S. (2018). Application of thin layer activation technique for monitoring corrosion of carbon steel in hydrocarbon processing environment. Applied Radiation and Isotopes, 135, 201–206.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Atik Setyani, Moch. Aditya Jheno Sheva Hermawan, Imam Prabowo, Nur Amin

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

An author who publishes in the J-ENSITEC (Journal of Engineering and Sustainable Technology) agrees to the following terms:

- Author retains the copyright and grants the journal the right of first publication of the work simultaneously licensed under the Creative Commons Attribution-ShareAlike 4.0 License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal

- The author is able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book) with the acknowledgment of its initial publication in this journal.

- The author is permitted and encouraged to post his/her work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of the published work